Today was another step in learning the boat and building a reliable underway workflow. Here is a breakdown of the exact checks I ran, what worked, and the issues I found.

Pre-Startup Checks

Battery and Electrical:

House batteries ON at the selector. Start battery ON at its dedicated switch. Verified battery monitor voltage, DC breakers, and ensured shore power was unplugged.

Engine Compartment:

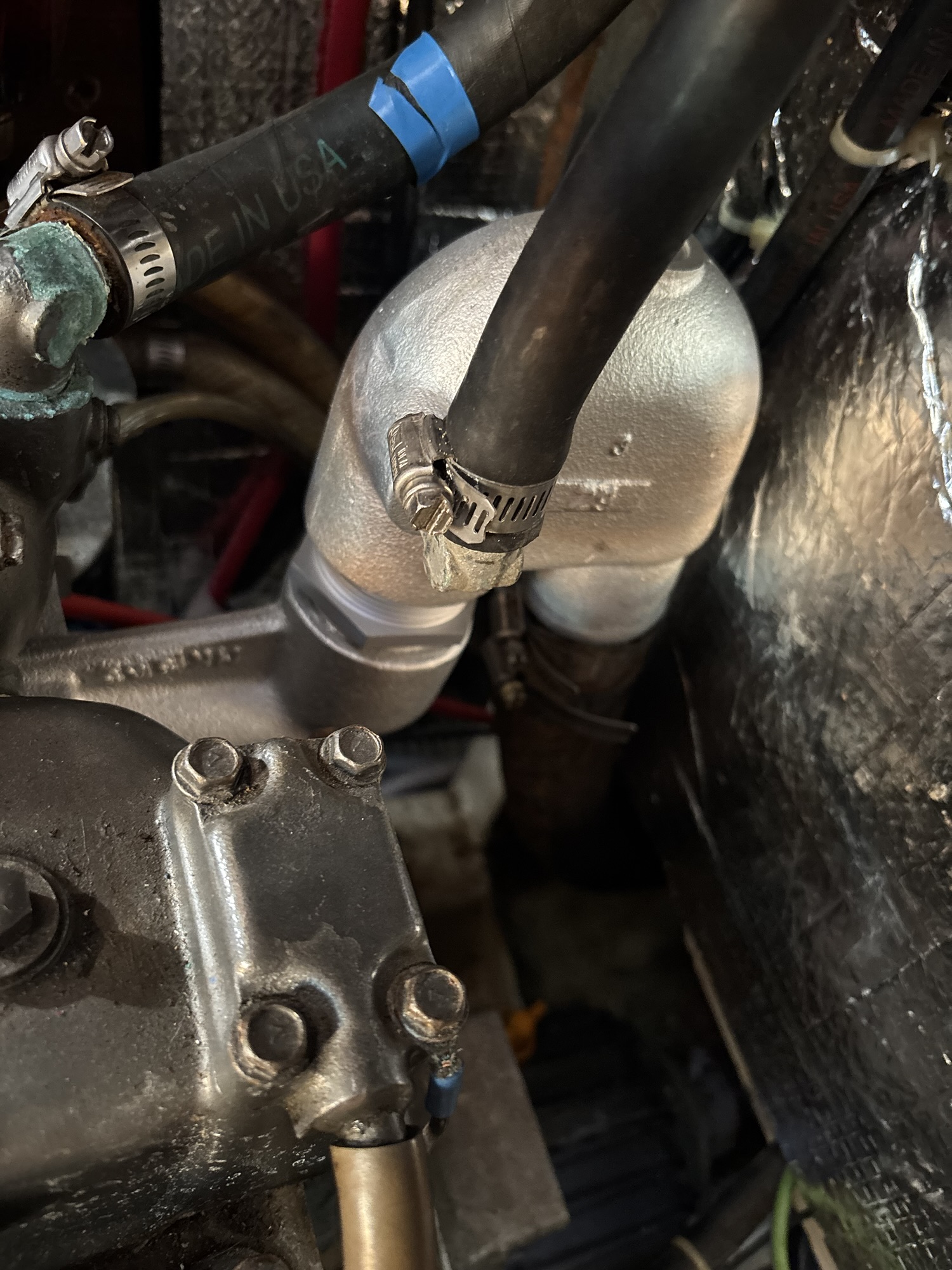

Inspected raw water hose, exhaust elbow (still corroded and scheduled for replacement), mounts, and belt. Checked oil level and coolant reservoir. Confirmed shaft packing gland was not leaking.

Bilge and Pumps:

Bilges mostly dry. Electric bilge pump works manually. Float switch non-functional. Manual bilge pump still not taking suction. Secondary Rule bilge pump not wired in.

Fuel and Water:

Fuel tank roughly half full. Freshwater pump cycles intermittently due to a likely worn check valve.

Dockside Departure Workflow

Lines and Fenders:

Lines adjusted for wind and tide. Fenders set mid-ship and aft.

Helm and Navigation:

Raymarine chartplotter powered on. Depth, wind, and speed pages loaded. Autopilot powered but still fails with a “no data” message.

Sails:

Main halyard clean and ready. Furling line and sheets free.

Engine Start and Warm-Up:

Glow plug heated for 10 seconds. Engine started immediately with water discharging from the exhaust. Throttle cable extremely stiff and hard to set. Tachometer initially dead, then jumped to an unrealistic reading while underway.

Underway in the Estuary

Motored at about 3–3.5 knots for the hour-long run out of the estuary. While underway:

Engine temperature stayed steady. No unusual vibration. Hand-steered due to the autopilot issue. Rudder play not noticeable.

Sail Checks

Main Hoist:

Tides track smooth. One luff slug out of its track (needs reseating). Sail shape looked good.

Jib:

Furler smooth. UV cover stitching worn and due for renewal.

Traffic Separation Scheme Reminder

While returning downwind toward the Bay Bridge, a tanker closed distance much faster than expected. Good reminder that big ships move deceptively fast and to exit channels early when possible.

Return Trip and Engine Notes

Before the bridge, I dropped sails and motored in. Engine stayed cool, discharged water normally, no leaks. Still could not precisely adjust RPM due to the stiff throttle cable. Tach remained erratic.

Autopilot Discovery

I eventually got the wheel pilot to engage after learning the correct sequence, but it still throws the “no data” error. Likely a Seatalk bus or fluxgate compass wiring issue that needs a deeper dive.

Berthing in Rain and Low Light

Returned around 4 PM before rain and darkness set in. Docking was smooth. Secured lines, shut down the engine, turned off both battery banks, and opened the cabin for ventilation.

Issues Identified for Follow-Up

High Priority:

Replace throttle, shift, and stop cables. Replace mixing elbow and riser. Diagnose tachometer irregularities. Repair autopilot data fault. Install functioning bilge float switch. Rebuild manual bilge pump.

Medium Priority:

Reseat mainsail luff slug. Repair bow-light wiring insulation. Replace toilet intake vent loop. Track down freshwater pump cycling issue. Repair dodger stitching.

Low Priority:

Clean up wiring behind panel. Renew jib UV stitching. Update stove propane cylinder to OPD valve.

Summary

The boat performed well overall and continues to show solid structure and reliable mechanical behavior. The remaining issues match the survey and are manageable. Once the cables are replaced and the autopilot is online, the boat will be fully ready for longer Bay and coastal trips.