Establishing Baseline Condition & Performing Initial Repairs

This week focused on systematically assessing the mechanical, electrical, plumbing, and structural condition of a 1990 Ericson 32-200. The goal was to build a clear technical baseline and begin addressing items that affect reliability, safety, and long-term offshore readiness.

The following summarizes key findings, diagnostics, and next steps.

1. Documentation, Identification & Compliance

1.1 Hull Identification Number (HIN)

Primary HIN confirmed on the starboard transom (ERY32915D090). Secondary “hidden” HIN not yet located (required by CA for registration verification). Inspection continues in typical locations: Under cockpit sole Inside cabinetry near major bulkheads Glassed into hull behind liners

1.2 Registration & COD

Vessel appears properly documented with USCG. Ongoing alignment between COD information and state requirements.

2. Plumbing & Sanitation Systems

2.1 Toilet System Backflow

Observation:

Toilet bowl was full of water after time away from the boat.

Technical Causes Identified:

Wet/dry selector left in wet mode. Intake seacock remained open. Vented loop location requires verification (height above waterline critical on Ericsons).

Corrective Measures Planned:

Store head with seacock closed + selector in dry. Inspect vented loop orientation and renew hoses as needed. Confirm survey recommendation: install or service the high vented loop between pump → toilet.

2.2 Holding Tank Vent

Hissing/bubbling traced to holding tank vent on the stern. Hose functions but will be replaced to reduce odor permeation per ABYC sanitation hose lifespan guidance.

3. Propulsion System – Yanmar 3GM30F

3.1 Dipstick – Not Located Yet

Dipstick not yet found despite multiple access attempts. The 3GM30F has two possible dipstick locations, only one active: Starboard low on block Port side beneath intake manifold Access is restricted by engine enclosure and adjacent structures.

Next Step:

Remove side panels, use inspection mirror, verify active dipstick tube, and proceed with full oil service.

3.2 Control Cables

Throttle, shift, and stop cables all exhibit high resistance. Replacement scheduled in line with 2023 survey recommendation.

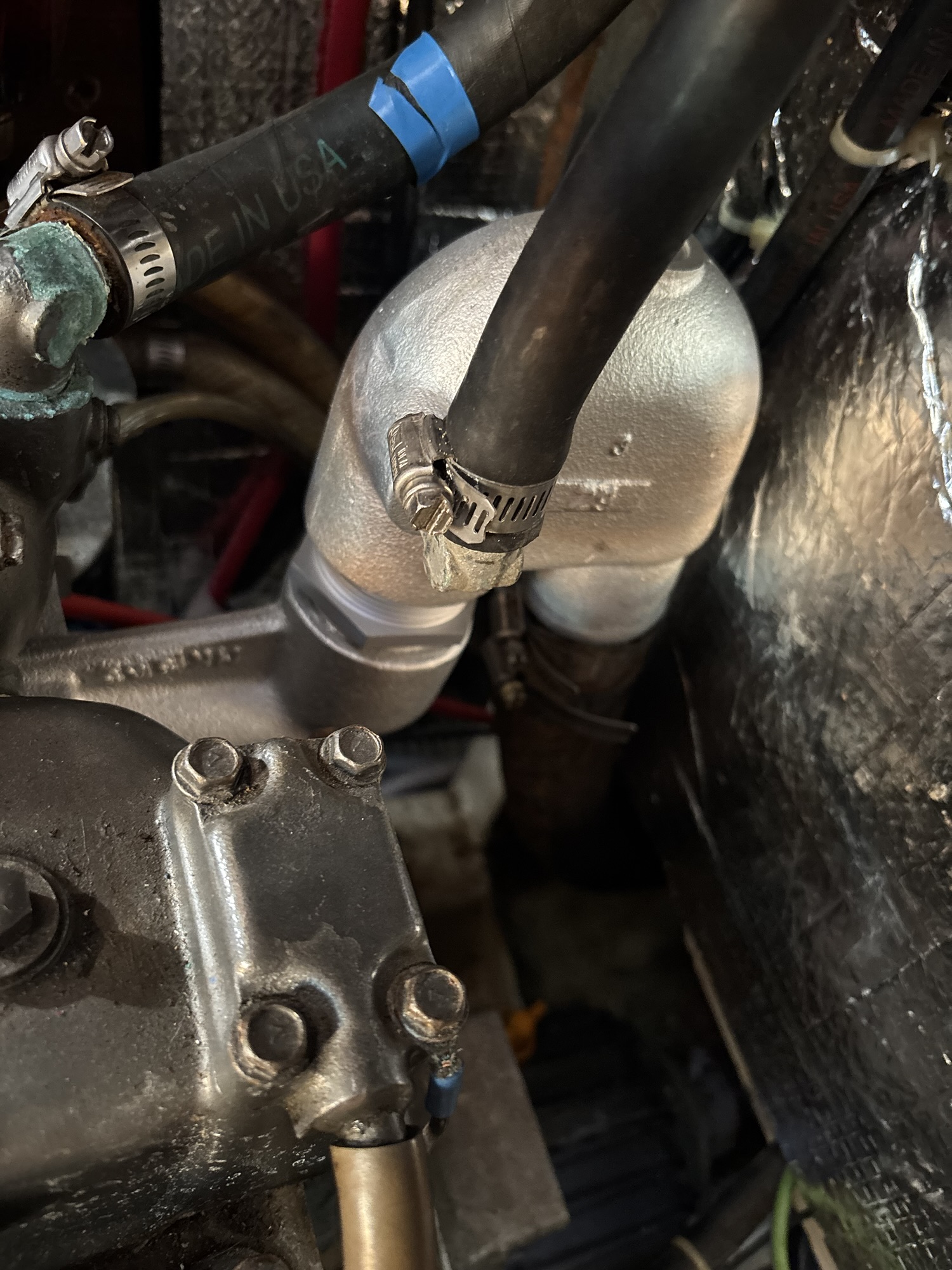

3.3 Exhaust Riser & Mixing Elbow

Findings:

Existing cast-iron mixing elbow shows significant corrosion and staining. Threaded nipple connecting elbow to riser is seized.

Corrective Actions Underway:

PB Blaster applied (multi-day soak). Plan to remove elbow/riser assembly and extract nipple on bench. Stainless elbow selected as replacement component. Nickel anti-seize prepared for installation. Exhaust hose to be inspected during disassembly.

3.4 Cooling System Hoses

Blue-striped hose confirmed as part of cooling circuit/vented loop system. Further cleaning and inspection planned.

3.5 Alternator Wiring

One white connector with blue wire found unconnected. Likely for indicator lamp or sensing circuit. Wire will be traced and correctly terminated or capped.

4. Steering & Rudder Systems

4.1 Emergency Tiller Tube

Vertical tube under cockpit contains water. Determined normal for this Ericson design where the rudder tube extends to hull penetration.

4.2 Rudder Condition

2023 survey noted a crack/delamination on upper trailing edge. Visual inspection to confirm condition and evaluate whether additional work is required.

4.3 Steering Cables

Cables move freely but are dry. Plan to clean and lubricate sheaves and tension system.

5. Electrical System

5.1 Bilge Pumping System – Comprehensive Rebuild Needed

Survey findings confirmed during inspection:

Primary diaphragm pump operates manually only. Automatic/manual control switch unpowered. Rule 1500 submersible pump present but not wired or plumbed. Manual pump does not take suction. No strainer on any suction side. No vented loop on discharge. No high-water alarm.

Planned Rebuild Includes:

Dedicated fused feed for automatic/manual switch New float switch New high-water float + audible alarm Service or replace Whale manual pump Install intake strainers Install proper vented loop high under coaming Replace hoses and secure all clamps

5.2 Wiring Cleanup & Safety

Several dead-end wires and unlabeled conductors identified. Will be traced, labeled, or removed. Plan to reorganize DC panel backside wiring for maintainability and safety.

5.3 Shore Power

GFCI functional. ELCI + galvanic isolator recommended upgrade per ABYC E-11.

6. Electronics & Network Systems

6.1 Starlink Connectivity Issue

Symptom:

Speeds measured at ~0.03 Mbps.

Findings:

RJ45 Ethernet cable run to the external antenna appears degraded (sun exposure and outdoor routing). Starlink Ethernet adapter requires CAT5e/CAT6 certified cable.

Next Steps:

Replace with UV-rated outdoor CAT6 Add drip loops and proper strain relief Re-test throughput

7. Structural & Deck Systems

7.1 Chainplate Moisture

Areas of elevated moisture near chainplates noted in 2023 survey. Inspection ongoing; rebedding will be scheduled.

7.2 Aft Cabin Moisture

Light dampness observed near aft bulkhead. Likely source: cockpit sole fittings or steering access hatch. Resealing planned.

8. Priority Action Plan – Week Two

Mechanical

Locate and access dipstick Replace throttle, shift, and stop cables Remove and rebuild exhaust riser/mixing elbow Inspect and verify exhaust hose routing and back-siphon protection

Electrical

Begin full bilge system rebuild Add high-water alarm Label/troubleshoot DC conductors Clean and secure wiring behind DC panel

Plumbing

Inspect toilet vented loop height Replace holding tank vent hose Confirm all sanitation hose conditions

Network / Electronics

Replace Starlink Ethernet cable and re-test

Structural

Continue inspection for hidden HIN Begin chainplate rebedding planning

Conclusion

Week One established a clear technical baseline for the Ericson 32-200 and identified priority systems requiring attention. Overall, the vessel shows strong core structure and a solid engine platform. Most work items are age-related and can be addressed through systematic refit practices. Future logs will include detailed procedures, part numbers, and measurements for owners seeking to complete similar upgrades on Ericson models or comparable 30–35 ft production sailboats.